Projects Gallery

FDC Coils

Ultraviolet Air & Surface Purification

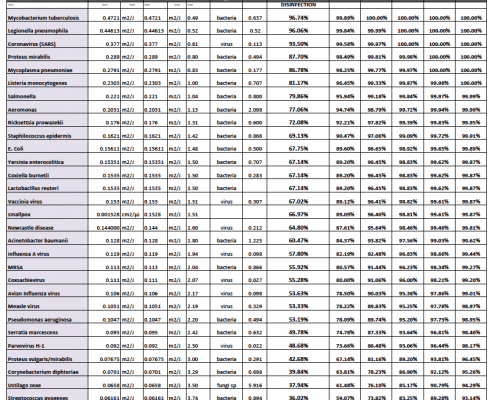

INDEPENDENT TESTING OBJECTIVE

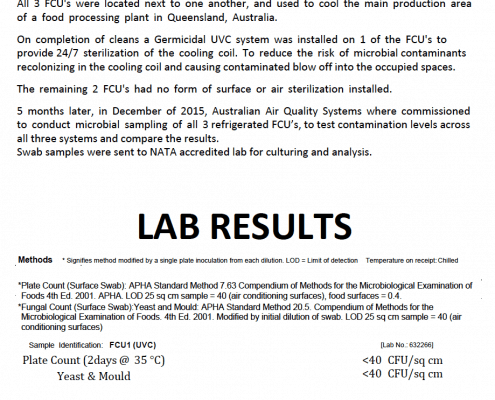

In June of 2015, 3 cool room coils where professionally cleaned by a National HVAC Cleaning Contractor, as part of a regular servicing and maintenance program.

All 3 FCU’s were located next to one another, and used to cool the main production area of a food processing plant in Queensland, Australia. On completion of cleans a Germicidal UVC system was installed on 1 of the FCU’s to provide 24/7 sterilization of the cooling coil. To reduce the risk of microbial contaminants recolonizing in the cooling coil and causing contaminated blow off into the occupied spaces.

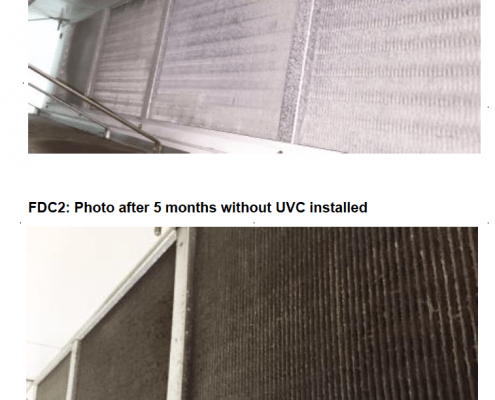

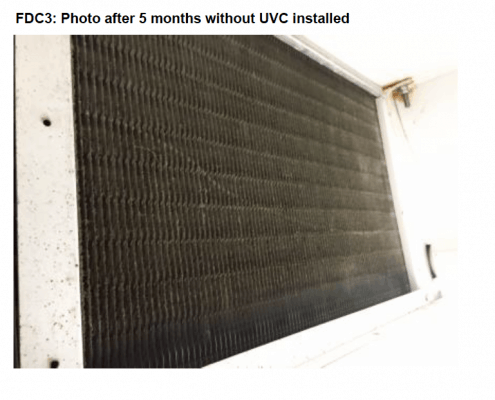

The remaining 2 FCU’s had no form of surface or air sterilization installed. 5 months later, in December of 2015, Australian Air Quality Systems where commissioned

to conduct microbial sampling of all 3 refrigerated FCU’s, to test contamination levels across all three systems and compare the results. Swab samples were sent to NATA accredited lab for culturing and analysis.

LAB RESULTS

Sample Identification: [Lab No.: 632266]

FCU1 (UVC Installed)

Plate Count (2days @ 35 °C) 40 CFU/sq cm Yeast & Mould 40 CFU/sq cm Sample Identification: [Lab No.: 632267]

FCU2 (No UVC)

Plate Count (2days @ 35 °C) 980 CFU/sq cm Yeast & Mould 760 CFU/sq cm Sample Identification: [Lab No.: 632268]

FCU3 (No UVC)

Plate Count (2days @ 35 °C) 1230 CFU/sq cm Yeast & Mould 150 CFU/sq cm

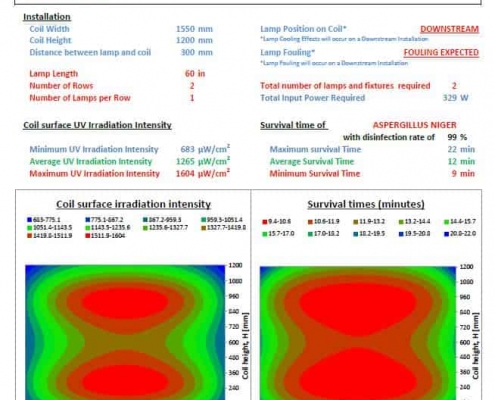

HVAC Coils

HVAC Cooling Coil Purification

- T6 Size Globes – 17000 hrs run time with rubber boot to protect critical components

- UV Stabilized Conduit, protects Teflon coated ballast wire for exceptional performance and durability.

- Aluminium Reflectors offer 70 – 80% reflection of UVC, maximize intensity to the cooling coil and protect components against accelerated decay.

- Sturdy construction, in this instance, 24mm aluminium extrusion was used to stand the test of time, and servicemen.

- Pop riveted mounting brackets ensure a secure, durable installation.

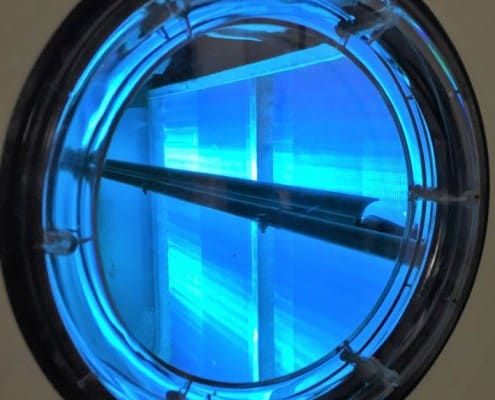

- Poly-carbonate 200 mm view port with rubber gasket for inspection and safety purposes.

- Externally mounted ballasts with optional BMS connectivity.

- Australian UV systems are functional, durable, tidy and consistent across Australia.

- Unit Specific, Irradiation Data Sheets available to ensure the required dose of UVC is achieved for every installation.

- Call us on 0452 383 484 for more information

Biowall

Outside Air Purification

Micro-organisms in the air can cause spoilage and effect valuable shelf life. Penicillium Digitatum is a mesophilic fungus found in the soil of citrus-producing areas and is a major source of post-harvest decay in fruits and is responsible for the widespread post-harvest disease in Citrus fruit, known as green rot or mould.

To manage the risk of Penicillium Digitatum from being introduced to the fruit via the rooms “outside air supply” we designed a bespoke UV Bio-wall system to retrofit to the current HVAC system providing fresh air to the fruit processing/de-greening rooms.

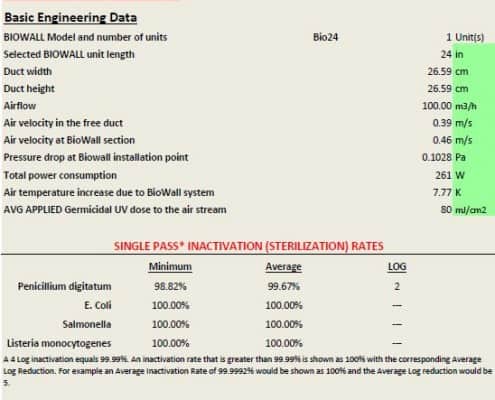

In just one pass the Biowall is able to destroy 99.67% as a minimum inactivation figure.

The main challenge was retrofitting the Bio-wall to fit the existing PVC ducting and to fabricate a system that was “serviceable” at height.

To do this we installed a 24” UVC Biowall inside a 1mtr x 200mm diameter Aluminium cylinder for maximum reflection and UV efficiency. The system tapered down to the existing duct with transition flanges at either end. The Bio-wall section is removable and tethered by chain to hang for servicing or when lamp change out is required in 2 – 3 years.

All lamps are Teflon coated in the unlikely event there should be a breakage, this ensures the quartz would be contained in the sock.

The Biowall system is also monitored 24/7 and linked to a controls interface for remote On/Off controls, lamp timer, fault alerts and alerts facility personal when lamps are due to be replaced after 17000hrs.