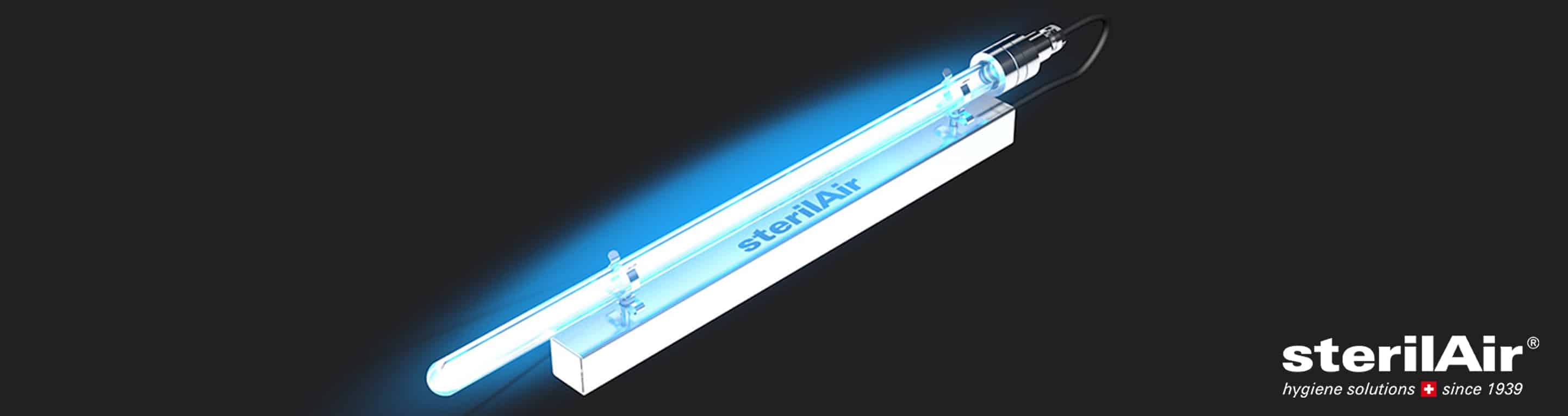

Stainless steel flow-through systems

sterilAir AQD-ST series of stainless steel flow-through equipment offer compact small systems with annular geometry up to six-flame UV-C systems with negative irradiation geometry.

All relevant parts of sterilAir AQD-ST consist of a particularly high-grade stainless steel (WN 1.4404/ 316L), which have been additionally double pickled and passivated to increase the corrosion resistance.

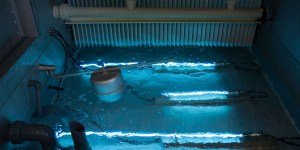

Superior technology for sterility

Microorganisms find ideal growth conditions within recirculated water or technical fluids. Chemical disinfectants lead to a number of undesirable side effects, such as changes in surface tension of the medium, corrosion, foam and odour.

UV-C treatment of water does not encounter such problems. It is a purely physical process without chemical residues. At the same time, cost-effectiveness of this disinfection method is impressive.